-

insimbi engagqwali umugqa wokukhiqiza usinki wamanzi

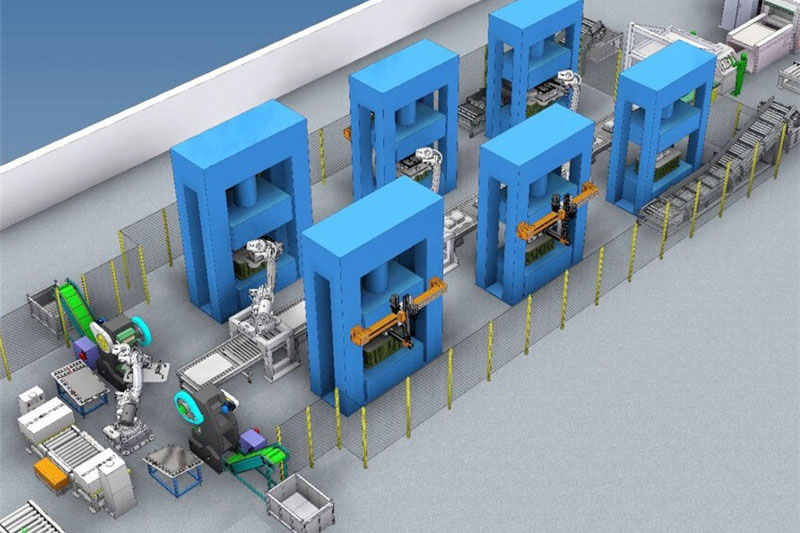

Ulayini wokukhiqiza usinki wamanzi wensimbi engenasici ulayini wokukhiqiza ozishintshayo ohlanganisa izinqubo ezifana nokuqaqa ikhoyili yensimbi, ukusika, nokugxiviza ukuze kumiswe osinki. Lo mzila wokukhiqiza usebenzisa amarobhothi ukuze athathe isikhundla somsebenzi wezandla, okuvumela ukuphothulwa ngokuzenzakalela kokukhiqizwa kukasinki.

Ulayini wokukhiqiza usinki wamanzi wensimbi engenasici uqukethe izingxenye ezimbili eziyinhloko: iyunithi yokuhlinzeka ngezinto ezibonakalayo kanye neyunithi yokugxiviza kukasinki. Lezi zingxenye ezimbili zixhunywe iyunithi yokudlulisa izinto, esiza ukuthuthwa kwezinto phakathi kwazo. Iyunithi yokuhlinzeka ngezinto ezibonakalayo ihlanganisa okokusebenza njengamakhoyili amakhoyili, ama-laminator amafilimu, ama-flatteners, ama-cutters, nezitaki. Iyunithi yokudlulisa impahla iqukethe amakalishi okudlulisa, imigqa yokupakisha impahla, nemigqa yokugcina yephalethi engenalutho. Iyunithi yokugxiviza ihlanganisa izinqubo ezine: ukusika i-engeli, ukwelula okuyisisekelo, ukunwetshwa kwesibili, ukusika emaphethelweni, okubandakanya ukusetshenziswa komshini wokunyathelisa we-hydraulic kanye ne-robot automation.

Amandla okukhiqiza alo mugqa yizingcezu ezi-2 ngomzuzu, nokukhishwa konyaka kwezingcezu ezingaba ngu-230,000.

-

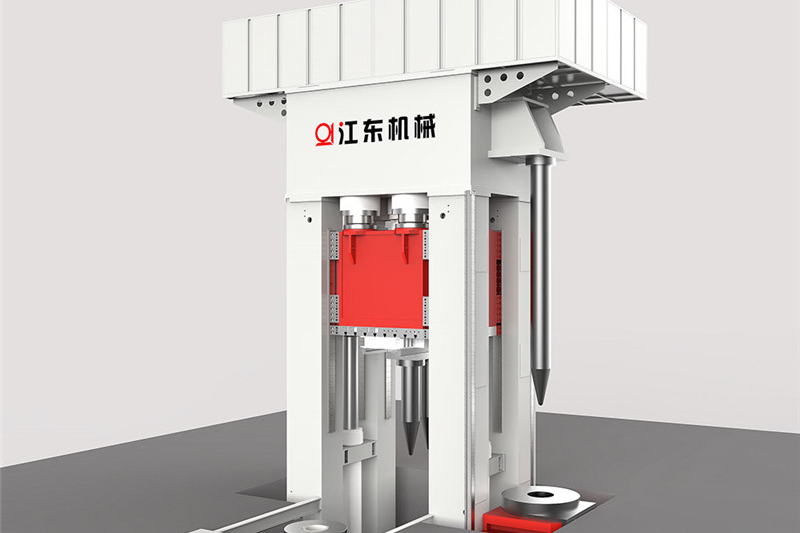

I-SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

Ukuqinisekisa ukulawula okunembile ngesikhathi senqubo yokubumba, umshini wokunyathelisa we-hydraulic ufakwe uhlelo oluthuthukisiwe lokulawula i-servo hydraulic. Lolu hlelo luthuthukisa ukulawula indawo, ukulawula isivinini, ukulawula isivinini sokuvula okuncane, kanye nokunemba kwepharamitha yokucindezela. Ukunemba kokulawula ukucindezela kungafinyelela ku-±0.1MPa. Amapharamitha afana nokuma kwama-slide, isivinini esibheke phansi, isivinini sokucindezela ngaphambilini, isivinini esincane sokuvula, isivinini sokubuyisela, kanye ne-exhaust frequency ingasethwa futhi ilungiswe phakathi kwebanga elithile kusikrini esithintwayo. Isistimu yokulawula iyonga amandla, inomsindo ophansi kanye nomthelela omncane we-hydraulic, ihlinzeka ngokuzinza okuphezulu.

Ukuze kubhekwane nezinkinga zobuchwepheshe ezifana nemithwalo engalingani ebangelwa izingxenye ezibunjiwe ze-asymmetric kanye nokuchezuka kogqinsi emikhiqizweni emikhulu emincane eyisicaba, noma ukuze kuhlangatshezwane nezidingo zenqubo ezifana nokwemboza okungaphakathi kwesikhunta kanye nokudilizwa okuhambisanayo, umshini wokucindezela we-hydraulic ungahlonyiswa ngedivayisi yokulinganisa yamakhona amane eguqukayo ngaleso sikhathi. Le divayisi isebenzisa izinzwa zokususwa ezinemba okuphezulu kanye nama-valve e-servo ephendula imvamisa ephezulu ukuze ilawule isenzo sokulungisa esivumelanayo sama-actuator angamasilinda amane. Ifinyelela ukunemba kokulinganisa okuphezulu kwamakhona amane kufika ku-0.05mm kulo lonke ithebula.

-

I-LFT-D i-fiber ende iqinise umugqa wokukhiqiza wokubumba oqondile we-thermoplastic

I-LFT-D ende ifayibha eqinisiwe yomugqa wokukhiqiza wokubumba oqondile we-thermoplastic iyisixazululo esibanzi sokwenza izinto ezihlanganisiwe zekhwalithi ephezulu. Lo mugqa wokukhiqiza uqukethe isistimu yokuqondisa intambo ye-fiber yengilazi, i-twin-screw glass fiber plastic mixing extruder, i-block heat heat, isistimu yokubamba impahla yerobhothi, umshini wokunyathelisa osebenza ngomshini osebenza kanzima, kanye neyunithi yokulawula emaphakathi.

Inqubo yokukhiqiza iqala ngokudla kwe-fiber yengilazi okuqhubekayo ku-extruder, lapho isikwa futhi ikhishwe ibe yifomu le-pellet. Ama-pellets abe eseshiselwa futhi abunjwe ngokushesha abe yisimo esifunwayo kusetshenziswa uhlelo lokubamba impahla yerobhothi kanye nomshini wokucindezela we-hydraulic osheshayo. Ngomthamo wokukhiqiza wonyaka we-300,000 kuya ku-400,000 imivimbo, lo mugqa wokukhiqiza uqinisekisa ukukhiqiza okuphezulu.

-

Isisetshenziswa seCarbon Fiber High Pressure Resin Transfer Molding (HP-RTM).

I-Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) iyisixazululo esisezingeni eliphezulu esakhiwe endlini ukuze kukhiqizwe izingxenye ze-carbon fiber zekhwalithi ephezulu. Lo mugqa wokukhiqiza ophelele uhlanganisa izinhlelo ozikhethela ukwenza kusengaphambili, umshini wokunyathelisa okhethekile we-HP-RTM, uhlelo lomjovo we-resin we-HP-RTM ophezulu, amarobhothi, isikhungo sokulawula umugqa wokukhiqiza, kanye nesikhungo somshini ozikhethela sona. Uhlelo lwe-HP-RTM lomjovo we-resin high-pressure luqukethe isistimu ye-metering, i-vacuum system, isistimu yokulawula izinga lokushisa, kanye nesistimu yokuthutha impahla eluhlaza kanye nesitoreji. Isebenzisa indlela yokujova enengcindezi ephezulu, enezingxenye ezintathu. Umshini wokunyathelisa oyisipesheli ufakwe isistimu yokulinganisa enamagumbi amane, enikeza ukunemba kokuleveli okuhlaba umxhwele okungu-0.05mm. Iphinde ibe namakhono okuvula okuncane, okuvumela imijikelezo yokukhiqiza esheshayo yemizuzu emi-3-5. Lo mshini uvumela ukukhiqizwa kwenqwaba kanye nokucubungula okuguquguqukayo okwenziwe ngokwezifiso kwezingxenye ze-carbon fiber.

-

I-Metal extrusion/hot die forging hydraulic press

I-Metal extrusion/hot die forging hydraulic press iwubuchwepheshe bokukhiqiza obusezingeni eliphezulu, obusebenzayo, kanye nokucubungula ukusetshenziswa okuphansi kwezingxenye zensimbi ezinama-chips amancane noma angekho nhlobo. Ithole ukusetshenziswa okubanzi ezimbonini ezahlukahlukene zokukhiqiza njengezimoto, imishini, imboni yokukhanya, i-aerospace, ezokuvikela kanye nemishini kagesi.

I-Metal extrusion/hot die forging hydraulic press iklanyelwe ngokukhethekile i-extrusion ebandayo, i-extrusion efudumele, i-forging efudumele, kanye nezinqubo zokwenza ukufa okushisayo, kanye nokuqedwa okunembayo kwezingxenye zensimbi.

-

titanium alloy superplastic forming hydraulic press

Umshini wokunyathelisa we-Superplastic Forming Hydraulic ungumshini okhethekile owenzelwe ukwakheka kwe-nethi eseduze kwezingxenye eziyinkimbinkimbi ezenziwe ngezinto ezilukhuni ukuzenza zibe nezigaba zokushisa zokuguquguquka ezincane kanye nokumelana nokuguquguquka okuphezulu. Ithola ukusetshenziswa okusabalele ezimbonini ezifana ne-aerospace, ezondiza, ezempi, ezokuvikela, nezitimela ezihamba ngesivinini esiphezulu.

Lo mshini womshini wokunyathelisa usebenzisa i-superplasticity yezinto zokwakha, njengama-alloys e-titanium, ama-alloys e-aluminium, ama-alloys e-magnesium, nama-alloys ashisa kakhulu, ngokulungisa usayizi wokusanhlamvu wezinto ezingavuthiwe zibe yisimo sepulasitiki. Ngokusebenzisa i-ultra-low pressure kanye nesivinini esilawulwayo, umshini wokunyathelisa uzuza ukuguqulwa kwe-superplastic yezinto. Le nqubo yokukhiqiza eyinguquko yenza kube lula ukukhiqizwa kwezingxenye kusetshenziswa imithwalo emincane kakhulu uma kuqhathaniswa namasu okwakha ajwayelekile.

-

Umshini wokucindezela we-hydraulic wamahhala

I-Free Forging Hydraulic Press ingumshini okhethekile owenzelwe imisebenzi emikhulu yamahhala yokufoga. Ivumela ukuphothulwa kwezinqubo ezihlukahlukene zokubumba ezifana nokwelula, ukucasula, ukubhoboza, ukunwetshwa, ukudweba ibha, ukusonteka, ukugoba, ukuguquguquka, nokuqoba ukuze kukhiqizwe amashafu, izinduku, amapuleti, amadiski, izindandatho, kanye nezingxenye ezakhiwe yizimo eziyindilinga neziyisikwele. Ifakwe izinto ezisizayo ezihambisanayo ezifana nemishini yokubumba, amasistimu okubamba impahla, amathebula wezinto ezijikelezayo, ama-anvils, nezindlela zokuphakamisa, abezindaba bahlanganisa ngaphandle komthungo nalezi zingxenye ukuze baqedele inqubo yokubumba. Ithola ukusetshenziswa okubanzi ezimbonini ezifana ne-aerospace kanye nezindiza, ukwakha imikhumbi, ukukhiqiza amandla, amandla enuzi, i-metallurgy, namakhemikhali e-petrochemicals.

-

I-Light Alloy Liquid Die Forging/semisolid forming Line Line

I-Light Alloy Liquid Die Forging Production Line iwubuchwepheshe besimanje obuhlanganisa izinzuzo zokulingisa nezinqubo zokubumba ukuze kuzuzwe ukwakheka komumo oseduze nenetha. Lo mzila wokukhiqiza omusha unikeza izinzuzo ezimbalwa, okuhlanganisa ukugeleza kwenqubo emfushane, ubungane bemvelo, ukusetshenziswa kwamandla okuphansi, ukwakheka kwengxenye efanayo, nokusebenza okuphezulu kwemishini. Iqukethe i-multifunctional CNC liquid die forging hydraulic press, i-aluminium liquid quantitative quantitative system, irobhothi, kanye nesistimu edidiyelwe yebhasi. Ulayini wokukhiqiza ubonakala ngokulawula kwawo kwe-CNC, izici ezihlakaniphile, nokuvumelana nezimo.

-

I-Vertical Gas Cylinder/Bullet Housing Drawing Production Line

I-Vertical Gas Cylinder/Bullet Housing Drawing Production Line yakhelwe ngokukhethekile ukukhiqizwa kwezingxenye ezimise okwenkomishi (ezimise okomphongolo) ezinomkhawulo ongezansi owugqinsi, njengeziqukathi ezihlukahlukene, amasilinda egesi, nezindlu zezinhlamvu. Lo mugqa wokukhiqiza unika amandla izinqubo ezintathu ezibalulekile: ukucasula, ukubhoboza, nokudweba. Kuhlanganisa okokusebenza okunjengomshini wokuphakelayo, isithando somlilo esiphakathi nendawo, ibhande lokuthutha, irobhothi eliphakelayo/isandla semishini, ukucasula nokushaya umshini wokunyathelisa we-hydraulic, itafula lamaslayidi elineziteshi ezimbili, irobhothi lokudlulisa isandla/isandla somshini, ukudweba umshini wokucindezela osebenzisa amanzi, kanye nohlelo lokudlulisa impahla.

-

I-Gas Cylinder Horizontal Drawing Production Line

Umugqa wokukhiqiza ovundlile we-cylinder yegesi uklanyelwe inqubo yokwakheka enwebekayo yamasilinda egesi amade kakhulu. Isebenzisa indlela yokwakheka yokwelula evundlile, ehlanganisa iyunithi yekhanda lomugqa, irobhothi elilayisha impahla, umshini wokucindezela ovundlile we-stroke ovundlile, indlela yokuhlehlisa impahla, kanye neyunithi yomsila womugqa. Lo mugqa wokukhiqiza unikeza izinzuzo ezimbalwa ezifana nokusebenza okulula, isivinini sokwakheka okuphezulu, ukushaywa unhlangothi eside, kanye nezinga eliphezulu lokuzenzekelayo.

-

I-Gantry Straightening Hydraulic Press for Plates

I-gantry straightening hydraulic press yethu yakhelwe ngqo ukuqondisa kanye nokwenza izinqubo zamapuleti ensimbi ezimbonini ezifana ne-aerospace, ukwakha umkhumbi, kanye ne-metallurgy. Izinto zokusebenza ziqukethe ikhanda lesilinda eligudlukayo, uzimele we-gantry ohambayo, kanye netafula lokusebenza elingaguquki. Ngokukwazi ukwenza ukugudluka okuvundlile kukho kokubili ikhanda lesilinda kanye nohlaka lwe-gantry ngobude betafula lokusebenza, i-gantry straightening hydraulic press yethu iqinisekisa ukulungiswa kwepuleti okunembile nokuphelele ngaphandle kwanoma yiziphi izindawo ezingaboni lutho. Isilinda esiyinhloko somshini wokunyathelisa sifakwe umsebenzi wokuya phansi kwe-micro-movement, okuvumela ukuqondisa kwepuleti okunembile. Ukwengeza, i-worktable yakhelwe ngamasilinda okuphakamisa amaningi endaweni yamapuleti asebenzayo, okwenza kube lula ukufakwa kwamabhulokhi okulungisa ezindaweni ezithile futhi kusiza ekuphakamiseni amapuleti.ifting of the plate.

-

I-Automatic Gantry Straightening Hydraulic Press ye-Bar Stock

I-gantry yethu ezenzakalelayo yokuqondisa i-hydraulic iwumugqa wokukhiqiza ophelele oklanyelwe ukuqondisa kahle nokulungisa isitoko sebha yensimbi. Iqukethe iyunithi yokuqondisa ye-hydraulic ephathwayo, isistimu yokulawula ukutholwa (okuhlanganisa ukutholwa kwesiqephu sokusebenza esiqondile, ukutholwa kwe-engeli ye-workpiece, ukutholwa kwebanga lephoyinti lokuqondisa, nokutholwa kokuqondisa kokususwa), isistimu yokulawula i-hydraulic, kanye nesistimu yokulawula kagesi. Lo mshini wokunyathelisa osebenza ngezindlela ezihlukahlukene we-hydraulic uyakwazi ukwenza ngokuzenzakalelayo inqubo yokuqondisa isitokwe sebha yensimbi, iqinisekise ukunemba okuphakeme nokusebenza kahle.