Umugqa Wokukhiqiza Oshisayo Osheshayo Wensimbi Enamandla Aphezulu (i-Aluminium)

Izici ezibalulekile

Umugqa Wokukhiqiza wenzelwe ukwenza ngcono inqubo yokukhiqiza izingxenye zezimoto ngokusebenzisa ubuchwepheshe bokunyathela okushisayo. Le nqubo, eyaziwa ngokuthi ukunyathela okushisayo e-Asia kanye nokuqina kokucindezela eYurophu, ihilela ukufudumeza izinto ezingenalutho ziye ekushiseni okuthile bese uzicindezela ezikhumbeni ezifanele kusetshenziswa ubuchwepheshe bokucindezela kwe-hydraulic ngenkathi kugcinwa ingcindezi ukuze kufezwe isimo esifiselekayo futhi kuguqulwe isigaba sezinto zensimbi. Indlela yokunyathela okushisayo ingahlukaniswa ngezindlela zokunyathela okushisayo eziqondile nezingaqondile.

Izinzuzo

Enye yezinzuzo ezibalulekile zezingxenye zesakhiwo ezinesitembu esishisayo ukwakheka kwazo okuhle kakhulu, okuvumela ukukhiqizwa kwamajiyometri ayinkimbinkimbi anamandla angavamile okudonseka. Amandla aphezulu ezingxenye ezinesitembu esishisayo enza kube lula ukusebenzisa amashidi ensimbi amancane, kunciphisa isisindo sezingxenye ngenkathi kugcinwa ubuqotho besakhiwo kanye nokusebenza kokuphahlazeka. Ezinye izinzuzo zifaka:

Imisebenzi Yokuhlanganisa Encishisiwe:Ubuchwepheshe bokunyathela okushisayo kunciphisa isidingo sokushisela noma ukusebenza kokuxhumanisa, okuholela ekusebenzeni kahle okuthuthukisiwe kanye nokuqina komkhiqizo.

I-Springback kanye ne-Warpage encishisiwe:Inqubo yokunyathela ngokushisa inciphisa ukuguquguquka okungafuneki, njenge-springback yengxenye kanye ne-warpage, iqinisekisa ukunemba okunembile kobukhulu futhi inciphise isidingo sokulungiswa kabusha okwengeziwe.

Amaphutha Ezingxenyana Ezimbalwa:Izingxenye ezinesitembu esishisayo zibonisa amaphutha ambalwa, njengokuqhekeka nokuqhekeka, uma kuqhathaniswa nezindlela zokwakha ubanda, okuholela ekuthuthukisweni kwekhwalithi yomkhiqizo kanye nokuncipha kwemfucuza.

I-Lower Press Tonnage:Ukunyathela okushisayo kunciphisa i-press tonnage edingekayo uma kuqhathaniswa namasu okwakha okubandayo, okuholela ekongeni izindleko kanye nokwanda kokusebenza kahle kokukhiqiza.

Ukwenza Ngokwezifiso Izakhiwo Zezinto:Ubuchwepheshe bokunyathela okushisayo buvumela ukwenza ngezifiso izakhiwo zezinto ngokusekelwe ezindaweni ezithile zengxenye, okwenza ngcono ukusebenza nokusebenza.

Ukuthuthukiswa Kwezakhiwo Ezincane Okuthuthukisiwe:Ukunyathela okushisayo kunikeza amandla okuthuthukisa isakhiwo esincane sezinto, okuholela ekuthuthukisweni kwezakhiwo zemishini kanye nokuqina komkhiqizo okwandisiwe.

Izinyathelo Zokukhiqiza Ezilula:Ukunyathela okushisayo kususa noma kunciphisa izinyathelo zokukhiqiza eziphakathi nendawo, okuholela enqubweni yokukhiqiza elula, ukukhiqiza okuthuthukisiwe, kanye nezikhathi zokuhola ezimfushane.

Izinhlelo Zokusebenza Zomkhiqizo

Umugqa Wokukhiqiza Izitembu Ezishisayo Ezisheshayo Zensimbi Enamandla Kakhulu (i-Aluminium) uthola ukusetshenziswa okubanzi ekukhiqizweni kwezingxenye zomzimba ezimhlophe zezimoto. Lokhu kufaka phakathi ukuhlanganiswa kwezinsika, amabhampa, imishayo yeminyango, kanye nokuhlanganiswa kwezitimela zophahla ezisetshenziswa ezimotweni zabagibeli. Ngaphezu kwalokho, ukusetshenziswa kwezitembu ezithuthukisiwe ezivuselelwa yizitembu ezishisayo kuyahlolwa kabanzi ezimbonini ezifana nezindiza, ezokuvikela, kanye nezimakethe ezisafufusa. Lezi zitembu zinikeza izinzuzo zamandla aphezulu kanye nesisindo esinciphile okunzima ukukufeza ngezinye izindlela zokwakha.

Ekuphetheni, i-High-Strength Steel (Aluminium) High-Speed Hot Stamping Production Line iqinisekisa ukukhiqizwa okunembile nokuphumelelayo kwezingxenye zomzimba zezimoto eziyinkimbinkimbi. Ngokwakheka okuphezulu, ukusebenza okuncishisiwe kokuhlangana, amaphutha ancishisiwe, kanye nezakhiwo zezinto ezithuthukisiwe, lo mugqa wokukhiqiza unikeza izinzuzo eziningi. Ukusetshenziswa kwawo kudlulela ekukhiqizweni kwezingxenye zomzimba ezimhlophe zezimoto zabagibeli futhi kunikeza izinzuzo ezingaba khona ezindiza, ukuzivikela, kanye nezimakethe ezisafufusa. Tshala imali ku-High-Strength Steel (Aluminium) High-Speed Hot Stamping Production Line ukuze ufeze ukusebenza okuhle kakhulu, ukukhiqiza, kanye nezinzuzo zomklamo ezilula ezimbonini zezimoto kanye nezimboni ezihambisana nazo.

Kuyini ukunyathela okushisayo?

Ukunyathela okushisayo, okwaziwa nangokuthi ukuqina kwe-press eYurophu kanye nokwakheka kwe-hot press e-Asia, kuyindlela yokwakha izinto lapho i-blank ishiswa khona ekushiseni okuthile bese inyatheliswa futhi icinywe ngaphansi kwengcindezi kudayi ehambisanayo ukuze kufezwe isimo esifiselekayo futhi kubangele ukuguqulwa kwesigaba ezintweni zensimbi. Ubuchwepheshe bokunyathela okushisayo buhilela ukufudumeza amashidi ensimbi e-boron (anamandla okuqala angu-500-700 MPa) esimweni sokunyathela, ukuwadlulisela ngokushesha kudayi ukuze kunyatheliswe ngesivinini esikhulu, kanye nokucima ingxenye engaphakathi kwedayi ngesivinini sokupholisa esingaphezu kuka-27°C/s, kulandelwe isikhathi sokubamba ngaphansi kwengcindezi, ukuthola izingxenye zensimbi ezinamandla kakhulu ezinesakhiwo esifanayo se-martensitic.

Izinzuzo zokunyathela okushisayo

Amandla okuqina athuthukisiwe kanye nekhono lokwenza amajiyometri ayinkimbinkimbi.

Kuncishiswe isisindo sezingxenye ngokusebenzisa insimbi encane ngenkathi kugcinwa ubuqotho besakhiwo kanye nokusebenza kokuphahlazeka.

Ukuncipha kwesidingo sokujoyina imisebenzi efana nokushisela noma ukubopha.

Ingxenye encishisiwe yentwasahlobo kanye nokugoba.

Amaphutha ambalwa ezingxenyeni ezifana nokuqhekeka nokuqhekeka.

Izidingo eziphansi zokucindezela amathoni uma kuqhathaniswa nokwakheka okubandayo.

Amandla okulungisa izakhiwo zezinto ngokusekelwe ezindaweni ezithile zezingxenye.

Izakhiwo ezincane ezithuthukisiwe ukuze kusebenze kangcono.

Inqubo yokukhiqiza elula enezinyathelo ezimbalwa zokusebenza ukuze kutholakale umkhiqizo oqediwe.

Lezi zinzuzo zinegalelo ekusebenzeni kahle, ikhwalithi, kanye nokusebenza kahle kwezingxenye zesakhiwo ezishisiwe.

Imininingwane eyengeziwe mayelana nokushisa okushisayo

1. Ukunyathela Okushisayo vs Ukunyathela Okubandayo

Ukunyathela okushisayo kuyinqubo yokwakha eyenziwa ngemva kokushisa ishidi lensimbi, kuyilapho ukunyathela okubandayo kubhekisela ekunyatheleni okuqondile kweshidi lensimbi ngaphandle kokushisa kusengaphambili.

Ukunyathela okubandayo kunezinzuzo ezicacile kune-hot stamping. Kodwa-ke, futhi kukhombisa ezinye izinkinga. Ngenxa yokucindezeleka okuphezulu okubangelwa inqubo yokunyathela okubandayo uma kuqhathaniswa nokunyathela okushisayo, imikhiqizo ene-cold-stamp isengozini enkulu yokuqhekeka nokuqhekeka. Ngakho-ke, imishini yokunyathela enembile iyadingeka ukuze kunyathele okubandayo.

Ukunyathela okushisayo kuhilela ukufudumeza ishidi lensimbi emazingeni okushisa aphezulu ngaphambi kokunyathela kanye nokucima ngesikhathi esifanayo kudayi. Lokhu kuholela ekuguqulweni okuphelele kwesakhiwo sensimbi sibe yi-martensite, okuholela emandleni aphezulu asukela ku-1500 kuya ku-2000 MPa. Ngenxa yalokho, imikhiqizo enezitembu ezishisayo ibonisa amandla aphezulu uma kuqhathaniswa nezinye ezifakwe izitembu ezibandayo.

2. Ukugeleza Kwenqubo Yokunyathela Okushisayo

Ukunyathela okushisayo, okwaziwa nangokuthi "ukuqina kwe-press," kuhilela ukufudumeza ishidi elinamandla aphezulu elinamandla okuqala angu-500-600 MPa kuya emazingeni okushisa aphakathi kuka-880 no-950°C. Ishidi elishisayo libe selinyathela ngokushesha bese licinywa kudayi, kufezwe amazinga okupholisa angu-20-300°C/s. Ukuguqulwa kwe-austenite ibe yi-martensite ngesikhathi sokunyathela kuthuthukisa kakhulu amandla engxenye, okuvumela ukukhiqizwa kwezingxenye ezinyathelisiwe ezinamandla afinyelela ku-1500 MPa. Amasu okunyathela okushisayo angahlukaniswa ngezigaba ezimbili: ukunyathela okushisayo okuqondile kanye nokunyathela okushisayo okungaqondile:

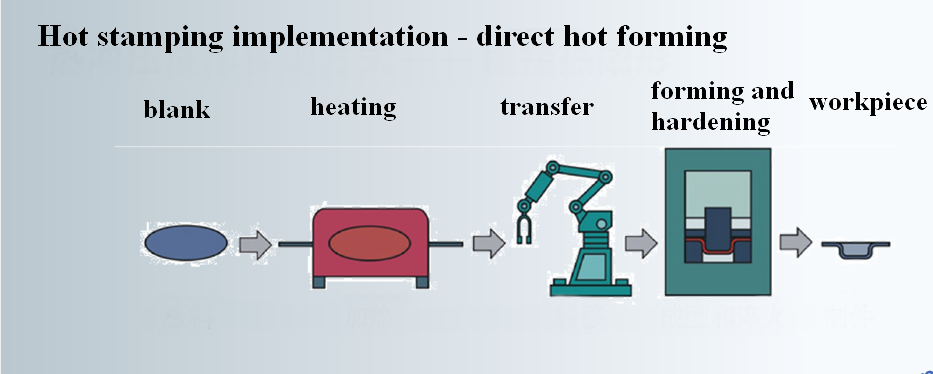

Ekunyathelweni okushisayo ngqo, i-blank eshisiwe ifakwa ngqo ku-die evaliwe ukuze inyathelwe futhi icinywe. Izinqubo ezilandelayo zifaka phakathi ukupholisa, ukusika umphetho kanye nokubhoboza imigodi (noma ukusika nge-laser), kanye nokuhlanza indawo.

I-Fiture1: imodi yokucubungula ukunyathela okushisayo--ukunyathela okushisayo okuqondile

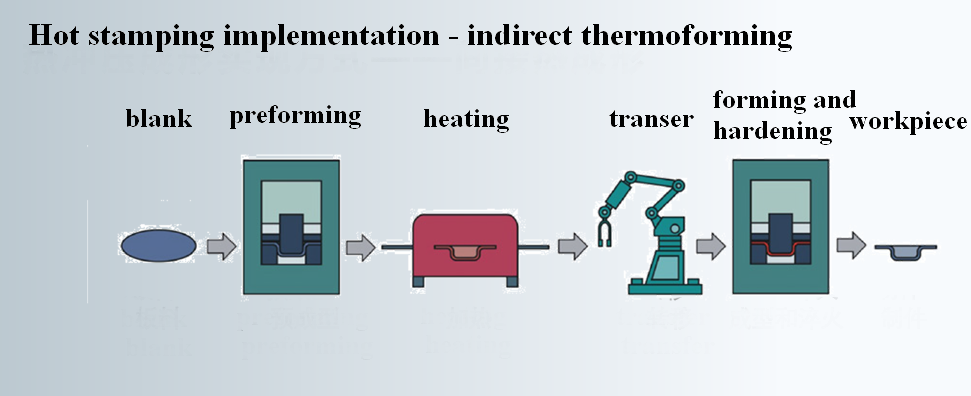

Enqubweni yokunyathela ngokushisa okungaqondile, isinyathelo sokuqala sokubumba okubandayo senziwa ngaphambi kokungena ezigabeni zokushisa, ukunyathela ngokushisa, ukusika umphetho, ukubhoboza imigodi, kanye nokuhlanza indawo.

Umehluko omkhulu phakathi kokunyathela okushisayo okungaqondile kanye nezinqubo zokunyathela okushisayo okuqondile ulele ekufakweni kwesinyathelo sokwakha ukwakheka okubandayo ngaphambi kokushisa ngendlela engaqondile. Ekunyatheleni okushisayo okuqondile, insimbi yeshidi ifakwa ngqo esithandweni sokushisa, kanti ekunyatheleni okushisayo okungaqondile, ingxenye ebumbeke njengokushisa ebumbeke kusengaphambili ithunyelwa esithandweni sokushisa.

Ukugeleza kwenqubo yokunyathelisa okushisayo okungaqondile ngokuvamile kuhilela izinyathelo ezilandelayo:

Ukwakheka kokwakheka okubandayo kusengaphambili - Ukushisa - Ukunyathela okushisayo - Ukusika imiphetho kanye nokubhoboza imigodi - Ukuhlanza indawo

I-Fiture2: imodi yokucubungula ukunyathela okushisayo--ukunyathela okushisayo okungaqondile

3. Imishini eyinhloko yokunyathela okushisayo ifaka isithando sokushisa, umshini wokucindezela oshisayo, kanye nesikhunta sokucindezela okushisayo

Isithando Sokushisa:

Isithando somlilo esifudumezayo sihlonyiswe ngamakhono okulawula ukushisa nokushisa. Siyakwazi ukufudumeza amapuleti anamandla aphezulu ukuze sifinyelele ekushiseni kokuphinda kusetshenziswe ngaphakathi kwesikhathi esithile, sifinyelele isimo se-austenitic. Sidinga ukukwazi ukuzivumelanisa nezidingo zokukhiqiza eziqhubekayo ezizenzakalelayo ezinkulu. Njengoba i-billet efudumele ingaphathwa kuphela ngamarobhothi noma izingalo zomshini, isithando somlilo sidinga ukulayisha nokulayisha okuzenzakalelayo ngokunemba okuphezulu kokubeka. Ngaphezu kwalokho, lapho kushiswa amapuleti ensimbi angagqokwanga, kufanele sihlinzeke ngokuvikelwa kwegesi ukuvimbela ukungcoliswa komhlaba kanye nokususwa kwe-carbonization ye-billet.

Umshini Wokucindezela Oshisayo:

Umshini wokucindezela uwumgogodla wobuchwepheshe bokucindezela okushisayo. Kudingeka ube nekhono lokucindezela okusheshayo nokubamba, kanye nokuhlonyiswa ngohlelo lokupholisa okusheshayo. Ubunzima bobuchwepheshe bomshini wokucindezela okushisa budlula kakhulu obomshini wokucindezela obandayo ovamile. Njengamanje, izinkampani ezimbalwa zakwamanye amazwe kuphela eziye zaba nekhono lokuklama nokukhiqiza ubuchwepheshe bomshini wokucindezela onjalo, futhi zonke zincike ekuthengeni kwamanye amazwe, okwenza kube kubi kakhulu.

Izikhunta Zokunyathela Ezishisayo:

Izikhunta ezishisayo zenza izigaba zokwakha kanye nezokucima. Esigabeni sokwakha, uma i-billet isifakwe emgodini wesikhunta, isikhunta siqeda ngokushesha inqubo yokunyathela ukuqinisekisa ukuqedwa kokwakheka kwengxenye ngaphambi kokuba izinto zidlule ekuguqulweni kwesigaba se-martensitic. Bese, singena esigabeni sokucima kanye nokupholisa, lapho ukushisa okuvela endaweni yokusebenza ngaphakathi kwesikhunta kudluliselwa khona njalo kusikhunta. Amapayipi okupholisa ahlelwe ngaphakathi kwesikhunta asusa ukushisa ngokushesha nge-coolant egelezayo. Ukuguqulwa kwe-martensitic-austenitic kuqala lapho izinga lokushisa le-workpiece lehla liye ku-425°C. Ukuguqulwa phakathi kwe-martensite ne-austenite kuphela lapho izinga lokushisa lifika ku-280°C, futhi indawo yokusebenza ikhishwa ku-200°C. Indima yokubamba kwesikhunta ukuvimbela ukwanda okungalingani kokushisa kanye nokufinyela ngesikhathi senqubo yokucisha, okungaholela ezinguqukweni ezibalulekile esimweni nasebukhulwini bengxenye, okuholela ekuqhekekeni. Ngaphezu kwalokho, kuthuthukisa ukusebenza kahle kokudlulisa ukushisa phakathi kwendawo yokusebenza kanye nesikhunta, okukhuthaza ukucima kanye nokupholisa okusheshayo.

Ngamafuphi, imishini eyinhloko yokufaka isitembu esishisayo ihlanganisa isithando sokushisa sokufinyelela izinga lokushisa elifunekayo, umshini wokucindezela oshisayo wokufaka isitembu esisheshayo nokubamba ngesistimu yokupholisa okusheshayo, kanye nezinhlobo zokufaka isitembu ezishisayo ezenza izigaba zokwakha kanye nezokucima ukuqinisekisa ukwakheka kwengxenye efanele kanye nokupholisa okuphumelelayo.

Ijubane lokupholisa lokucima alithinti nje kuphela isikhathi sokukhiqiza, kodwa futhi lithinta ukusebenza kahle kokuguqulwa phakathi kwe-austenite ne-martensite. Izinga lokupholisa linquma ukuthi hlobo luni lwesakhiwo sekristalu oluzokwakhiwa futhi luhlobene nomphumela wokugcina wokuqina kwento yokusebenza. Izinga lokushisa lokupholisa elibucayi lensimbi ye-boron licishe libe ngu-30℃/s, futhi kuphela lapho izinga lokupholisa lidlula izinga lokushisa lokupholisa elibucayi lapho ukwakheka kwesakhiwo se-martensitic kungathuthukiswa khona kakhulu. Lapho izinga lokupholisa lingaphansi kwezinga lokupholisa elibucayi, izakhiwo ezingezona eze-martensitic ezifana ne-bainite zizovela esakhiweni se-crystallization sento yokusebenza. Kodwa-ke, uma izinga lokupholisa liphezulu, lingcono, izinga lokupholisa liphezulu lizoholela ekuqhekekeni kwezingxenye ezakhiwe, futhi ububanzi bezinga lokupholisa elifanele kudingeka bunqunywe ngokuya ngokwakheka kwezinto kanye nezimo zenqubo yezingxenye.

Njengoba ukwakheka kwepayipi lokupholisa kuhlobene ngqo nosayizi wejubane lokupholisa, ipayipi lokupholisa ngokuvamile laklanywa ngokombono wokusebenza kahle kokudlulisa ukushisa okuphezulu, ngakho-ke isiqondiso sepayipi lokupholisa eliklanywe siyinkimbinkimbi kakhulu, futhi kunzima ukulithola ngokubhoboza ngomshini ngemva kokuqedwa kokuphonswa kwesikhunta. Ukuze kugwenywe ukuvinjelwa ukucutshungulwa ngomshini, indlela yokugcina iziteshi zamanzi ngaphambi kokuphonswa kwesikhunta ngokuvamile ikhethwa.

Ngenxa yokuthi isebenza isikhathi eside ku-200℃ kuya ku-880~950℃ ngaphansi kwezimo ezibandayo nezishisayo ezishintshanayo, izinto ezishisayo zokunyathela kumele zibe nokuqina okuhle kwesakhiwo kanye nokuqhuba ukushisa, futhi zingamelana nokungqubuzana okunamandla kokushisa okubangelwa yi-billet ekushiseni okuphezulu kanye nomphumela wokuguguleka okukhulu kwezinhlayiya zengqimba ye-oxide ewile. Ngaphezu kwalokho, izinto ezibunjiwe kufanele futhi zibe nokumelana okuhle kokugqwala ne-coolant ukuqinisekisa ukugeleza okubushelelezi kwepayipi lokupholisa.

Ukusika nokubhoboza

Ngenxa yokuthi amandla ezingxenye ngemva kokunyathelisa okushisayo afinyelela cishe ku-1500MPa, uma kusetshenziswa ukusika nokubhoboza ngokucindezela, izidingo zobukhulu bemishini zikhulu, futhi ukuguga konqenqema oluyisicaba kuyinto embi kakhulu. Ngakho-ke, amayunithi okusika nge-laser avame ukusetshenziselwa ukusika imiphetho nezimbobo.

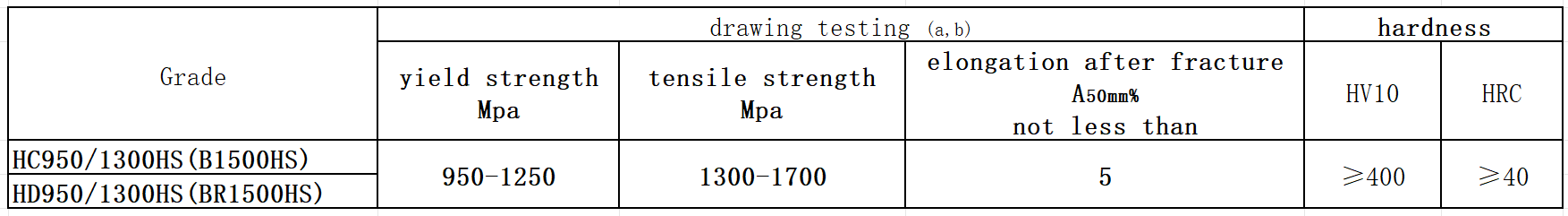

4. Amamaki avamile ensimbi yokunyathela eshisayo

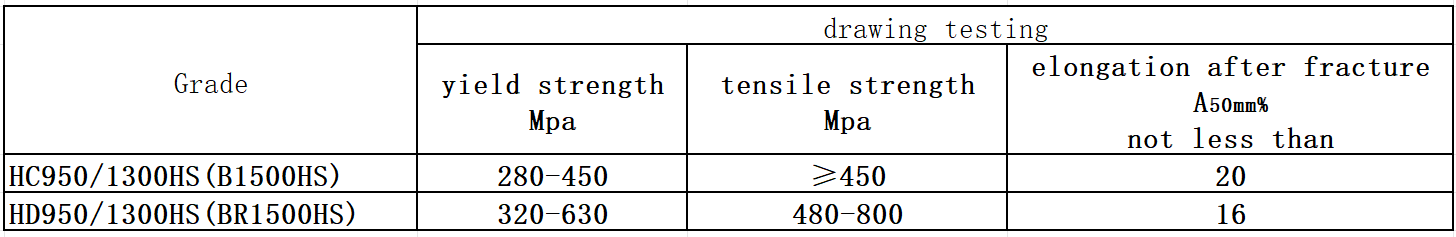

Ukusebenza ngaphambi kokunyathela

Ukusebenza ngemva kokunyathela

Njengamanje, izinga elivamile lensimbi yokunyathela eshisayo yi-B1500HS. Amandla okunyathela ngaphambi kokunyathela ngokuvamile aphakathi kuka-480-800MPa, futhi ngemva kokunyathela, amandla okunyathela angafinyelela ku-1300-1700MPa. Okusho ukuthi, amandla okunyathela epuleti lensimbi elingu-480-800MPa, ngokwakhiwa kwe-hot stamping, angathola amandla okunyathela angaba yizingxenye ezingu-1300-1700MPa.

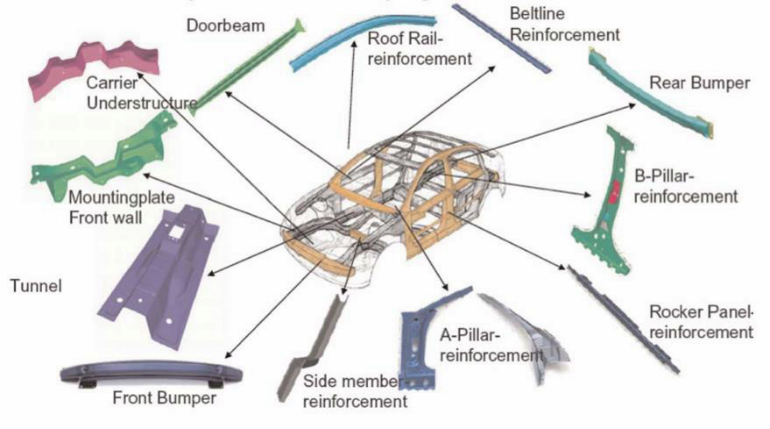

5. Ukusetshenziswa kwensimbi yokunyathela eshisayo

Ukusetshenziswa kwezingxenye ezishisayo kungathuthukisa kakhulu ukuphepha kokushayisana kwemoto futhi kufeze ukukhanya komzimba wemoto ngombala omhlophe. Njengamanje, ubuchwepheshe bokushisa busetshenzisiwe ezingxenyeni zomzimba ezimhlophe zezimoto zabagibeli, njengemoto, insika engu-A, insika engu-B, i-bumper, ugongolo lomnyango kanye nereyili yophahla nezinye izingxenye. Bheka isithombe 3 ngezansi isibonelo izingxenye ezifanelekela ukulinganisa ukukhanya.

isithombe 3: Izingxenye zomzimba ezimhlophe ezifanelekela ukunyathelisa okushisayo

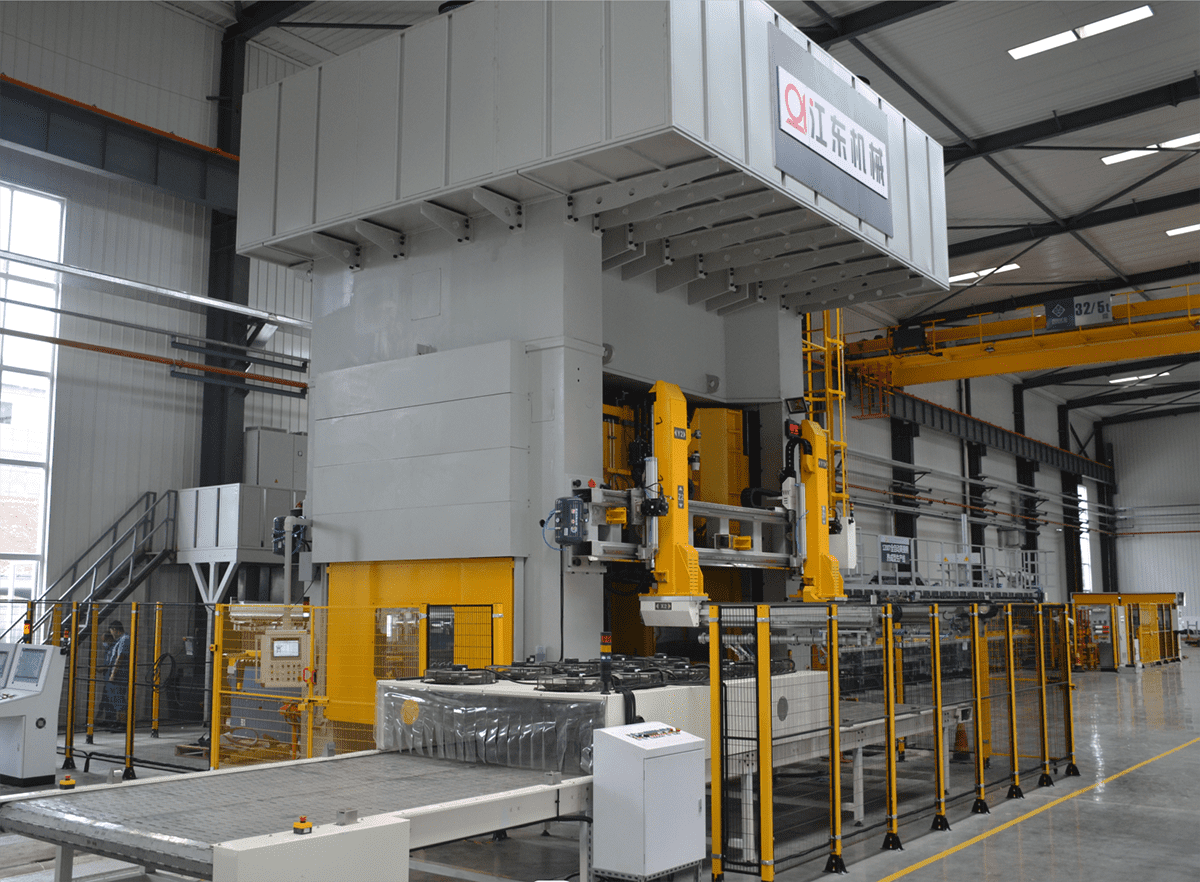

Isithombe 4: Umugqa Wokucindezela Oshisayo We-Jiangdong We-1200 Ton

Njengamanje, izixazululo zomugqa wokukhiqiza we-JIANGDONG MACHINERY hot stamping hydraulic press ziye zavuthwa kakhulu futhi zaqina, emkhakheni wokwakha i-hot stamping eShayina ungowesigaba esiholayo, futhi njengeyunithi engusekelasihlalo wegatsha le-China Machine Tool Association forging machinery kanye namayunithi angamalungu e-China Forging Machinery Standardization Committee, senze ucwaningo kanye nomsebenzi wokusebenzisa i-super high speed hot stamping kazwelonke yensimbi ne-aluminium, okudlale indima enkulu ekukhuthazeni intuthuko yemboni ye-hot stamping eShayina ngisho nasemhlabeni jikelele.