-

umugqa wokukhiqiza we-hydroforming wangaphakathi onengcindezi ephezulu

Ukwakhiwa kwengcindezi ephezulu yangaphakathi, okubuye kubizwe nge-hydroforming noma i-hydraulic forming, inqubo yokwakha impahla esebenzisa uketshezi njengendlela yokwakha futhi ifinyelela inhloso yokwenza izingxenye ezingenalutho ngokulawula ukucindezela kwangaphakathi nokugeleza kwempahla. IHydro Forming iwuhlobo lobuchwepheshe bokwenza i-hydraulic. Kuyinqubo lapho ishubhu lisetshenziswa njenge-billet, futhi i-tube billet icindezelwa emgodini wesikhunta ukuze kwakheke umsebenzi odingekayo ngokusebenzisa uketshezi olunomfutho ophezulu kakhulu kanye ne-axial feed. Ezingxenyeni ezinezimbazo ezigobile, i-tube billet idinga ukugotshwa kusengaphambili ibe yisimo sengxenye bese icindezelwa. Ngokusho kohlobo lwezingxenye ezakhayo, ukwakheka kwengcindezi ephezulu yangaphakathi kuhlukaniswe izigaba ezintathu:

(1) ukunciphisa i-tube hydroforming;

(2) ishubhu ngaphakathi kwe-axis egobayo i-hydroforming;

(3) i-multi-pass tube high-pressure hydroforming. -

I-Automated Sheet Metal Stamping Hydraulic Press Production Line yezimoto

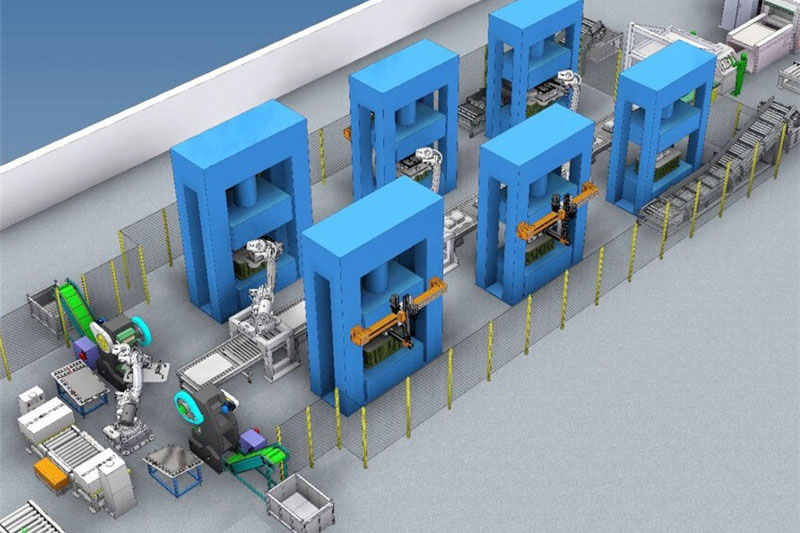

I-Fully Automated Automotive Sheet metal Stamping Hydraulic Press Production Line ishintsha umugqa wokuhlanganisa ovamile womshini wokuphakelayo nowokulayisha ngokuhlanganisa izingalo zerobhothi zokuphatha izinto ezizenzakalelayo nemisebenzi yokuthola. Lo mugqa wokukhiqiza unhlangothi oqhubekayo unika amandla ukukhiqiza okuhlakaniphile kumafekthri wokugxiviza ngokusebenza okungenamuntu ngokuphelele kuyo yonke inqubo yokukhiqiza.

Ulayini wokukhiqiza uyisixazululo esisezingeni eliphezulu esenzelwe ukwenza lula inqubo yokukhiqiza izingxenye zezimoto. Ngokushintshanisa umsebenzi wezandla ngezingalo zerobhothi, lo mugqa wokukhiqiza uzuza ukuphakelwa okuzenzakalelayo kanye nokuthulula izinto, kuyilapho uhlanganisa namakhono okuthola athuthukile. Isebenza ngendlela eqhubekayo yokukhiqiza i-stroke, iguqule izimboni zokugxiviza zibe yizindawo zokukhiqiza ezihlakaniphile.

-

I-Die Tryout Hydraulic Press ye-Automotive Part Tooling

I-Advanced Die Tryout Hydraulic Press, ethuthukiswe yi-JIANGDONG MACHINERY iyinguqulo ethuthukisiwe yomshini wokunyathelisa wensimbi onesenzo esisodwa esigxiviza nge-hydraulic. Idizayinelwe ngokuqondile ukulungisa iphutha lengxenye yezimoto, ihlanganisa amakhono anembile okulungisa i-stroke. Ngokunemba kokucushwa kahle okufika ku-0.05mm ngokushaywa ngakunye kanye nezindlela eziningi zokulungisa okuhlanganisa ukulungiswa kwamaphuzu amane okusebenza, ukulungiswa kwe-hydraulic servo, kanye nokunyakaza okuya phansi okungaphansi kwengcindezi, lo mshini wokunyathelisa we-hydraulic unikeza ukunemba okukhethekile kanye nokuguquguquka kokuhlolwa kwesikhunta nokuqinisekisa.

I-Advanced Die Tryout Hydraulic Press iyisixazululo esisezingeni eliphezulu esiklanyelwe ukuhlangabezana nezidingo ezihlukile zokulungiswa kwamaphutha kwezingxenye zezimoto. Wakhelwe phezu kwesisekelo somshini wokunyathelisa wensimbi onesenzo esisodwa esinyathela nge-hydraulic, lo mshini osungula izinto ezintsha wethula amakhono athuthukisiwe okulungisa ukushaya ukuze kuqinisekiswe ukuhlolwa okunembile kanye nokuqinisekiswa kwesikhunta sezimoto. Kunezindlela ezintathu zokulungisa ezihlukene ezitholakalayo, opharetha banokuguquguquka kokukhetha indlela yokulungisa efanele yezidingo zabo ezithile.

-

I-Die Spotting Hydraulic Press yokulungiswa kwe-Precision Mold

I-Die Spotting Hydraulic Press ingumshini okhethekile owenzelwe ukucubungula nokulungisa isikhunta ngokunembayo. Ifaneleka ngokukhethekile ukukhiqiza nokulungisa isikhunta sokugxiviza esiphakathi nendawo ukuya kwezinkulu, ihlinzeka ngokuqondana kwesikhunta okusebenzayo, ukulungisa iphutha okunembile, namandla okucubungula anembile. Lo mshini wokucindezela we-hydraulic uza ngezindlela ezimbili zesakhiwo: usebenzisa noma ngaphandle kwethuluzi lokuphetshwa isikhunta, kuye ngesigaba sesikhunta kanye nezidingo zenqubo yokubona. Ngokunemba kwayo okuphezulu kokulawula ukushaywa kanye nekhono lokushaywa kwe-stroke elilungisekayo, umshini wokunyathelisa we-hydraulic unikeza izinketho ezintathu ezihlukene zokuhlela kahle: ukulungiswa kwamaphoyinti amane ngomshini, ukulungiswa kwe-servo ye-hydraulic, kanye nokunyakaza okungaphansi kokucindezela phansi.

I-Die Spotting Hydraulic Press iyisixazululo esithuthuke kakhulu kwezobuchwepheshe esiklanyelwe ukucubungula nokulungisa isikhunta ezimbonini ezifana nezezimoto, i-aerospace, kanye neyokukhiqiza. Ukulawula ukushaywa kwayo okunembile kanye nokuguquguquka kwayo kuyenza ibe ithuluzi elibalulekile lokulungisa iphutha lesikhunta, ukuqondanisa, nokucubungula okunembile.

-

Ukugxiviza kwepuleti elimaphakathi nelijiyile kanye nokudweba umugqa wokukhiqiza we-hydraulic press

I-Medium-Thick Plate Deep Deep Drawing Production Line yethu ethuthukisiwe inemishini yokunyathelisa emihlanu ye-hydraulic, ama-roller conveyor, namabhande okuthutha. Ngesistimu yayo yokushintsha isikhunta esisheshayo, lo mugqa wokukhiqiza wenza ukushintshanisa isikhunta ngokushesha nangempumelelo. Iyakwazi ukufeza izinyathelo ezi-5 zokwenza kanye nokudlulisa ama-workpieces, ukunciphisa amandla okusebenza, nokwenza lula ukukhiqizwa okuphumelelayo kwempahla yasendlini. Wonke umugqa wokukhiqiza uzenzakalela ngokugcwele ngokuhlanganiswa kwe-PLC nokulawula okuphakathi, okuqinisekisa ukukhiqiza okuphezulu.

Ulayini Wokukhiqiza uyisixazululo sesimanje esiklanyelwe ukukhiqizwa okuphumelelayo kwezingxenye ezijulile ezivela kumapuleti anogqinsi oluphakathi. Ihlanganisa amandla nokunemba komshini wokunyathelisa we-hydraulic kanye nokuba lula kwezinhlelo zokubamba izinto ezizenzakalelayo, okuholela ekukhiqizeni okuthuthukisiwe kanye nokuncipha kwezidingo zabasebenzi.

-

I-Single-action Sheet metal Stamping Hydraulic Press

Ishidi lethu le-Single-action sheet metal Stamping Hydraulic Press litholakala kuzo zombili izinhlaka ezinekholomu nohlaka. Njengoba ufakwe umcamelo we-hydraulic owelula owehlela phansi, lo mshini uvumela izinqubo ezihlukahlukene ezifana nokwelula amashidi ensimbi, ukusika (ngomshini wokubhafa), ukugoba, nokuphephuka. Imishini ihlanganisa izinhlelo ezizimele ze-hydraulic kanye nekagesi, okuvumela ukulungiswa kanye nezindlela ezimbili zokusebenza: umjikelezo oqhubekayo (i-semi-automatic) nokulungiswa ngesandla. Izindlela zokusebenzisa umshini wokunyathelisa zihlanganisa isilinda se-hydraulic cushion esingasebenzi, ukwelula, nokwelula okuhlehlayo, ngokukhethwa okuzenzakalelayo phakathi kokucindezela okungaguquki nokushaywa kwemodi ngayinye. Isetshenziswa kakhulu embonini yezimoto ukugxiviza izingxenye zensimbi yeshidi elincanyana, isebenzisa isikhunta esinwebekayo, i-punching dies, kanye nesikhunta se-cavity ngezinqubo ezihlanganisa ukwelula, ukubhoboza, ukugoba, ukusika, nokuqeda kahle. Izicelo zakhona zidlulela ku-aerospace, ezokuthutha ngojantshi, imishini yezolimo, izinto zasendlini, neminye imikhakha eminingi.

-

I-Automobile Interior hydraulic Press And Production Line

I-Automobile Interior Press and Production Line eyakhiwe yi-JIANGDONG MACHINERY isetshenziselwa ikakhulukazi inqubo yokubumba yokucindezelwa okubandayo nokushisayo yezingxenye zangaphakathi zezimoto ezifana namadeshibhodi, okhaphethi, usilingi, nezihlalo. Ingahlonywa amasistimu okushisa afana nowoyela oshisayo noma isitimu esisuselwe ezidingweni zenqubo, kanye namadivayisi okuphakelayo nokuthulula okuzenzakalelayo, amahhavini okushisa abalulekile, kanye nezinto zokusebenza ze-vacuum ukuze zakhe ulayini wokukhiqiza ozishintshayo.

-

I-Automatic High-Speed Fine-Blanking hydraulic Press Line yezingxenye zensimbi

I-Automatic High-Speed Fine-Blanking hydraulic Press Line yakhelwe inqubo yokuvala ngokunemba kwezingxenye zensimbi, ebhekelela ikakhulukazi ukukhiqizwa kwezingxenye ezilungisa izihlalo zezimoto ezinjengama-rack, amapuleti amagiya, izilungisi zama-engeli, kanye nezingxenye zamabhuleki njengama-ratchets, izidladla, amapuleti okulungisa, ukudonsa izingalo, izinduku zokusunduza, amapuleti okusekela. Ngaphezu kwalokho, iyasebenza nasekukhiqizeni izinto ezisetshenziswa kumabhande ezihlalo, njengezilimi zebhande, izindandatho zegiya zangaphakathi, nezidladla. Lo mugqa wokukhiqiza uqukethe umshini wokucindezela we-hydraulic onemba kahle-blanking, ithuluzi lokuphakelayo elinezithonjana ezintathu kokukodwa, kanye nesistimu yokukhipha okuzenzakalelayo. Ihlinzeka ngokuphakelayo okuzenzakalelayo, ukuvala okuzenzakalelayo, ukuthuthwa kwengxenye okuzenzakalelayo, nemisebenzi yokusika imfucuza ezenzakalelayo. Umugqa wokukhiqiza ungafinyelela izinga lomjikelezo we-35-50spm.web, ipuleti lokusekela; I-Latch, iringi yangaphakathi, i-ratchet, njll.

-

I-Automobile Door Hemming Hydraulic Press

I-Automobile Door Hemming Hydraulic Press yakhelwe ngokukhethekile inqubo yokuhlanganisa kanye nokusebenza okungenalutho nokusikwa kweminyango yemoto kwesokunxele nakwesokudla, izivalo zetrunk, namakhava enjini. Ifakwe uhlelo olusheshayo lokushintsha ukufa, izindawo zokusebenza eziningi ezihambayo ngezindlela ezihlukahlukene, umshini ozenzakalelayo wokuhlanganisa ukufa, kanye nesistimu yokuqaphela ukufa.

-

insimbi engagqwali umugqa wokukhiqiza usinki wamanzi

Ulayini wokukhiqiza usinki wamanzi wensimbi engenasici ulayini wokukhiqiza ozishintshayo ohlanganisa izinqubo ezifana nokuqaqa ikhoyili yensimbi, ukusika, nokugxiviza ukuze kumiswe osinki. Lo mzila wokukhiqiza usebenzisa amarobhothi ukuze athathe isikhundla somsebenzi wezandla, okuvumela ukuphothulwa ngokuzenzakalela kokukhiqizwa kukasinki.

Ulayini wokukhiqiza usinki wamanzi wensimbi engenasici uqukethe izingxenye ezimbili eziyinhloko: iyunithi yokuhlinzeka ngezinto ezibonakalayo kanye neyunithi yokugxiviza kukasinki. Lezi zingxenye ezimbili zixhunywe iyunithi yokudlulisa izinto, esiza ukuthuthwa kwezinto phakathi kwazo. Iyunithi yokuhlinzeka ngezinto ezibonakalayo ihlanganisa okokusebenza njengamakhoyili amakhoyili, ama-laminator amafilimu, ama-flatteners, ama-cutters, nezitaki. Iyunithi yokudlulisa impahla iqukethe amakalishi okudlulisa, imigqa yokupakisha impahla, nemigqa yokugcina yephalethi engenalutho. Iyunithi yokugxiviza ihlanganisa izinqubo ezine: ukusika i-engeli, ukwelula okuyisisekelo, ukunwetshwa kwesibili, ukusika emaphethelweni, okubandakanya ukusetshenziswa komshini wokunyathelisa we-hydraulic kanye ne-robot automation.

Amandla okukhiqiza alo mugqa yizingcezu ezi-2 ngomzuzu, nokukhishwa konyaka kwezingcezu ezingaba ngu-230,000.

-

Ulayini Wokukhiqiza Izitembu oshisayo wesivinini esikhulu we-ultral high-Strength Steel (Aluminium)

Ulayini Wokukhiqiza Izitembu oshisayo wesivinini esikhulu wensimbi ephezulu Yamandla Amandla (i-Aluminium) iyisixazululo sesimanje sokukhiqiza sokukhiqiza izingxenye zomzimba zezimoto ezinomumo oyinkimbinkimbi kusetshenziswa indlela yokushisa eshisayo. Enezici ezinjengokuphakela impahla ngokushesha, umshini wokucindezela osebenza ngomshini oshisayo oshisayo oshisayo, isikhunta samanzi abandayo, isistimu yokubuyisa impahla ezenzakalelayo, kanye nezinketho zokucubungula ezilandelayo ezifana nokuqhunyiswa kwesibhamu, ukusika nge-laser, noma uhlelo lokusika oluzenzakalelayo nokuvala, lo mugqa wokukhiqiza unikeza ukusebenza okukhethekile nokusebenza kahle.

-

I-Ultra High Strength Steel (i-Aluminium) I-Automatic Cold Cutting /umugqa Wokukhiqiza ongenalutho

I-Ultra High Strength Steel (Aluminium) I-Automatic Cold Cutting Production Line iyisistimu ezenzakalelayo yesimanje eyenzelwe ukucutshungulwa kwensimbi enamandla noma i-aluminium ngemuva kokugxivizwa okushisayo. Isebenza njengokushintshwa okuphumelelayo kwemishini yokusika ye-laser yendabuko. Lo mzila wokukhiqiza uqukethe izinkinobho ezimbili ze-hydraulic ezinamadivaysi okusika, izingalo ezintathu ze-robotic, uhlelo lokulayisha nokukhipha okuzenzakalelayo, kanye nesistimu yokudlulisela ethembekile. Ngamakhono ayo okuzenzakalelayo, lo mugqa wokukhiqiza usiza izinqubo zokukhiqiza eziqhubekayo neziphezulu.

I-Ultra High Strength Steel (Aluminium) Automatic Cold Cutting Production Line ithuthukiswe ngokukhethekile ukusetshenzwa kwangemuva kwensimbi enamandla aphezulu noma izinto ze-aluminium kulandela izinqubo ezishisayo zokugxiviza. Inikeza isixazululo esinokwethenjelwa sokubuyisela izindlela zokusika ze-laser ezinzima futhi ezidla isikhathi. Lo mugqa wokukhiqiza uhlanganisa ubuchwepheshe obuthuthukisiwe, amathuluzi anembayo, kanye ne-automation ukuze kuzuzwe ukukhiqiza okungenamthungo nokusebenza kahle.